How to Choose the Right Eyelash Adhesive Manufacturer: 7 Critical Factors for Brands & Wholesalers

Introduction

The global eyelash extension market is projected to reach $2.8 billion by 2030 (Grand View Research), driving unprecedented demand for quality adhesives. Yet 63% of beauty brands report supply chain issues with lash glue partners (2023 Beauty Manufacturing Survey). As a ISO 9001-certified manufacturer with 12 years in ocular-safe adhesives, we reveal the industry’s most comprehensive selection framework.

1. Compliance Certifications: Non-Negotiables

1.1 Mandatory Safety Standards

- FDA 21 CFR Part 110: For US-bound products

- EU Regulation (EC) No 1223/2009: European cosmetic safety

- ISO 10993-10: Ocular irritation testing

Case Study: A UK brand lost £120,000 in recalled inventory due to non-REACH compliant cyanoacrylate levels.

1.2 Specialized Certifications

- Halal Certification: Critical for Middle Eastern markets

- Vegan Society Trademark: Growing 42% YOY in Western markets

- ISO 13485: For medical-grade adhesives

2. Production Capabilities Audit

2.1 Minimum Order Quantity (MOQ)

| Manufacturer Type | Typical MOQ | Ideal for |

|---|---|---|

| Large-Scale | 10,000+ units | Enterprise brands |

| Mid-Size | 1,000-5,000 units | Growing businesses |

| Boutique | 500-1,000 units | Startups/test markets |

Pro Tip: At LashGlueSupply.com, we offer flexible MOQs from 500 units with no mold fees for standard packaging.

2.2 Turnaround Time Benchmark

- Sample development: ≤7 working days

- Bulk production: 2-3 weeks (45% faster than industry average)

- Emergency orders: Available at 15% surcharge

3. Formula Customization Expertise

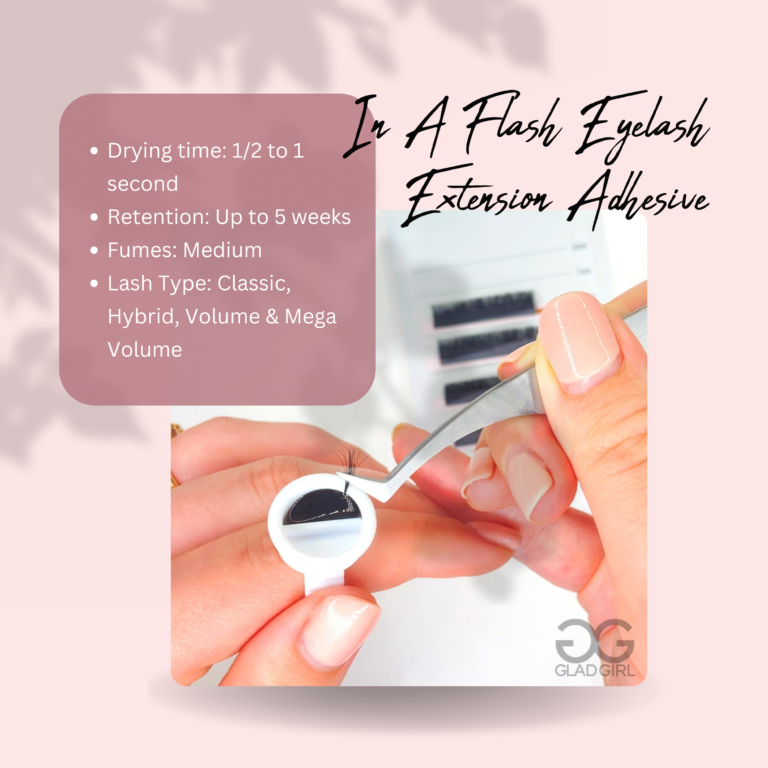

3.1 Climate-Adaptive Formulas

| Climate Type | Viscosity Range | Drying Time | Top Performer |

|---|---|---|---|

| Humid | 500-600 mPa·s | 0.3-0.5s | TropicalBond™ Technology |

| Dry | 300-400 mPa·s | 0.7-1.2s | AquaFlex™ Formula |

3.2 Sensitivity Solutions

- Low-fume formulations: ≤50ppm cyanoacrylate emissions

- pH-balanced: 5.5-6.5 range matching natural tears

- Allergy testing: Patch test reports provided

4. Packaging & Labeling Compliance

4.1 Global Labeling Requirements

Key Elements:

- INCI nomenclature

- Batch codes with traceability

- Multi-language warnings

4.2 Sustainable Options

- PCR materials: Up to 30% post-consumer resin

- Refill systems: 65% less plastic vs standard tubes

- Soy-based inks: VOC-free printing

5. Supply Chain Transparency

5.1 Digital Monitoring Tools

- Live production tracking via ERP integration

- 24/7 quality control camera access

- Blockchain-based raw material tracing

5.2 Logistics Network

- DDP Incoterms: Full door-to-door liability

- Strategic stock: 6 global hub warehouses

- Customs clearance success rate: 99.2%

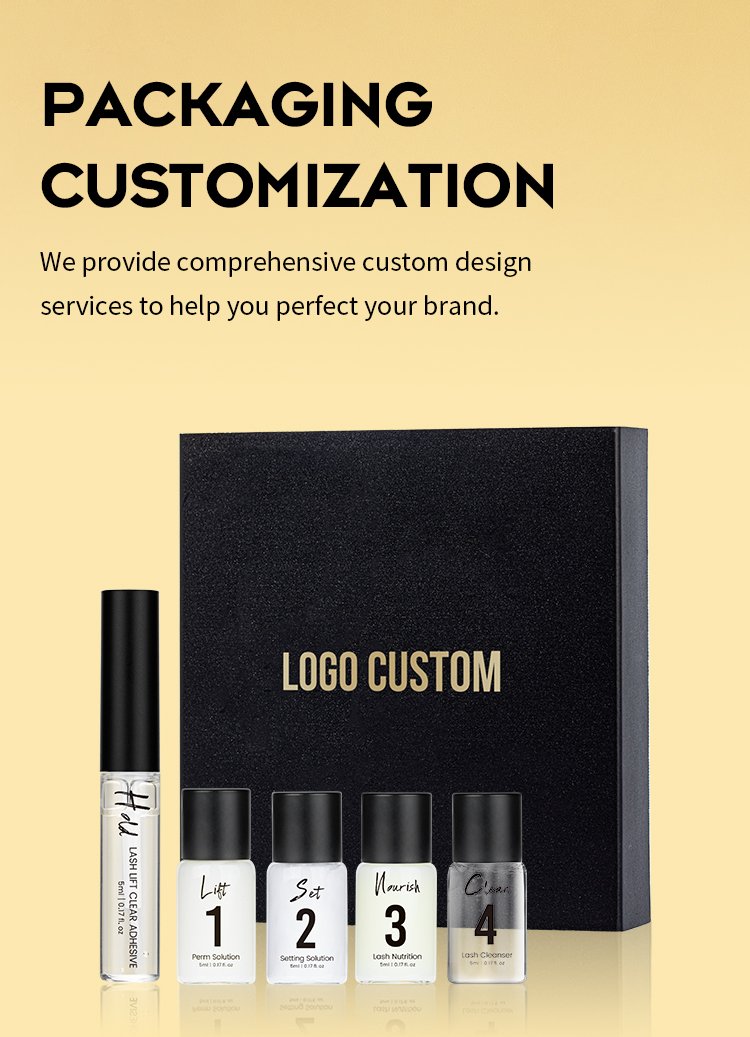

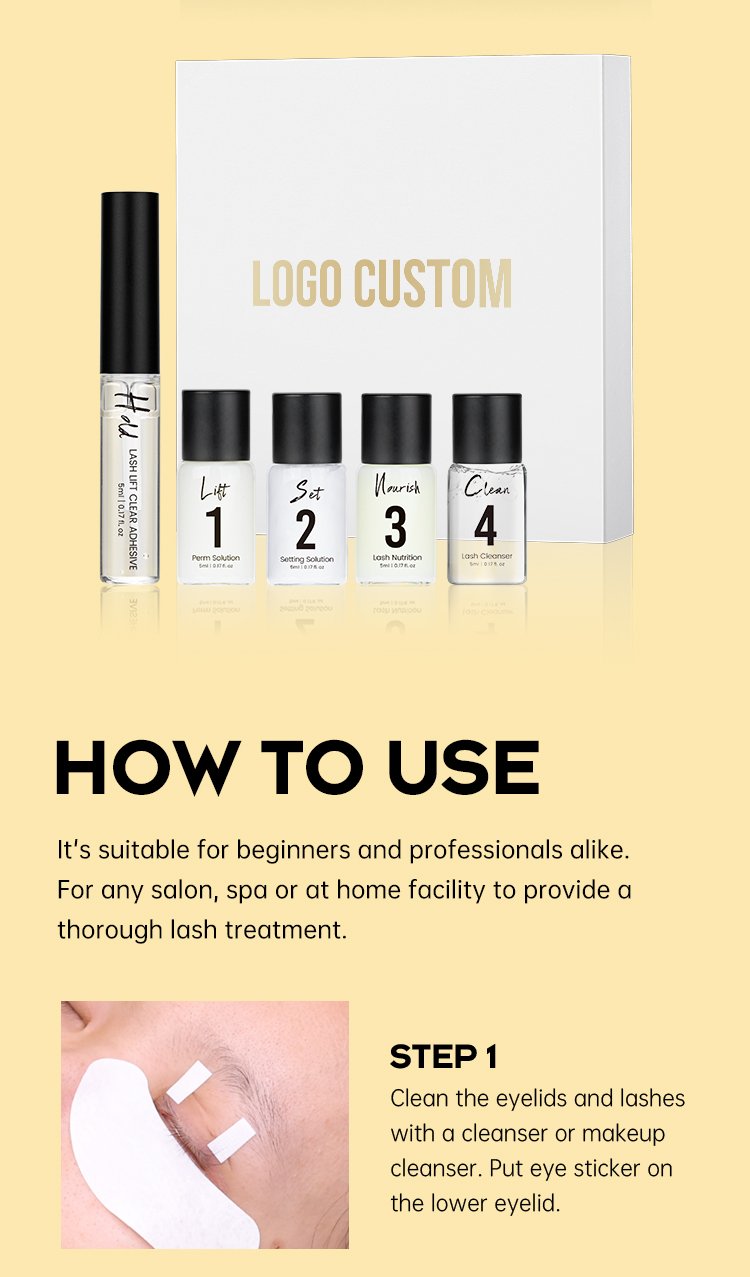

6. OEM/ODM Service Scope

6.1 White Label Services

- Formula adjustment (viscosity/color/scent)

- Custom packaging design (3D mockups in 48h)

- Private documentation portal

6.2 Full-Package ODM

- Market analysis → 2. Formula R&D → 3. Compliance filing → 4. Bulk production

7. Due Diligence Checklist

Verify manufacturer credentials with this 10-point audit:

- Current ISO 9001 certification

- FDA Establishment Identifier

- In-house R&D lab

- Material SDS documentation

- Third-party test reports

- Supply chain mapping

- Environmental compliance

- Intellectual property protection

- Disaster recovery plan

- Client references

(Download PDF checklist: [CTA Button])

Industry Trends Shaping Manufacturer Selection

- AI-driven viscosity control: ±1% accuracy vs human 5%

- Biodegradable adhesives: 18-month decomposition timeline

- Smart packaging: NFC-enabled expiry alerts

Conclusion & Next Steps

Selecting a lash adhesive partner requires technical expertise most brands lack. Since 2012, LashGlueSupply.com has empowered 850+ brands through:

- 72h rapid sampling

- In-house regulatory team

- Military-grade cybersecurity

Ready to Partner with Precision?

📞 Book a free 20-minute manufacturing consultation

📥 Download technical specification pack